Nutraceuticals &

Cosmeceuticals

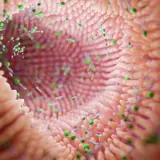

Our microencapsulation solutions can help improve product stability, efficacy, sensory experiences, and nutrient bioavailability, using natural and biodegradable materials that are safer and free from microplastics.

Discover new possibilities to improve performance with advanced encapsulation

Stability control

Explore how your most sensitive ingredients can become more stable and reduce overdosing.

Natural formulations

Discover new encapsulation alternatives that are natural, vegan, biodegradable, and microplastic-free.

Enteric delivery

Controlled and targeted delivery to improve bioavailability and nutrient absorption.

Exemplary case studies showing shelf-life extension of vitamin C and Lactobacillus rhamnosus using IamFluidics’ patented SlimBead™ encapsulation technology.

Extended shelf live

IN-AIR MICROFLUIDICS™ excels in ingredient encapsulation compared to spray drying, spray-cooling, spray-freezing, extrusion, fluid-bed coating, and melt injection. Our patented technology has proven to deliver superior results with the encapsulation of vitamins, curcumin, omega-3 oil, phytonutrients, and even anaerobic probiotics showing higher survival rates, lower oxidation, and reduced loss of potency.

The monodispersity delivered by our method ensures higher control and homogeneity of microcapsules that positively affect user sensory perceptions around taste and texture, but also improve absorption.

Flavor and fragrance market leader:

“Wow, amazing! It was very impressive to see how you work and what you can do“

According to a successful serial entrepreneur food technologist:

“You and your team have built something with real breakthrough potential. Encapsulated peptides instead of injection has such a huge potential and weight loss programs are a super interesting application.”

From peer-reviewed scientific review:

“Important progress in scale-up through in-air microfluidics.”

Food-grade microgel capsules tailored for anti-obesity strategies through microfluidic preparation (Curr. Opin. Food Sci., 2022).

Digestion using INFOGEST model by Brodkorb et al. (2019). Study in collaboration with Wageningen University & Research: Deng et al. Food Hydrocol. (2025).

Controlled release

SlimBead™ unique bi-gel composition enables enteric protection and tunable intestinal release of actives.

A natural way to eat less

The ileal brake

✓ No drugs

Natural food formulation without synthetic APIs

✓ Endogenous GLP-1 release

Promotes body’s own satiety hormones by targeting ileal brake activation

✓ No injections

Oral capsules instead of injections

✓ Industry compatible

Withstands shear and thermal treatments unlike other liposomal products

Meeting consumer demands

for sustainable products

Encapsulation is widely used to improve product stability and protect sensitive compounds against moisture, heat, oxidation, and degradation. It can also support better product bioavailability, nutrient absorption, and advanced sensory control, such as masking undesired smell, taste, or color.

Most brands in the market currently use traditional encapsulation that produces polydisperse (uneven) particles, often containing microplastics and animal-derived materials in their composition. There is a growing demand for sustainable, vegan, and clean-label products. Still, one of the main challenges faced by the industry is to support sustainability claims without compromising product performance and stability.

With our patented IN-AIR MICROFLUIDICS™ technology, we can encapsulate oils, vitamins, minerals, enzymes, live cells, probiotics, proteins, and a wide range of high-end ingredients using natural, biodegradable, and plant-based encapsulation solutions to produce monodisperse microcapsules with size ranging from 30µm to 3mm.

It is possible to customize microparticles' color, shape, size, and composition to achieve superior performance and increase differentiation in markets where players use claims around the same active ingredients.

Innovative & customizable

IamFluidics can customize microparticles to control stability, organoleptic properties, and delivery. We make solid, porous, capsule, and fibrous micromaterials from all renowned biodegradable polymers:

“If we can jet it, we can make it.”

Post-gastric release

Our enteric formulations can be tuned to provide protection and targeted delivery of active ingredients with post-stomach controlled release for optimal absorption. The time and conditions of release can be configurable to ensure that microparticles survive the stomach and arrive intact in the intestine, presenting new opportunities to develop market solutions for very sensitive materials such as probiotics for gut health, since our encapsulation process is mild and has proven survival rates of approximately 100% for certain probiotic strains.

Reduced overages

Often, higher dosing of ingredients must be added to products to compensate for expected losses in nutrient potency that occur during processing to ensure label claims are met. Given the high costs of many key ingredients, this overage can impact the cost of goods and margins over time. Encapsulation helps protect nutrients, reducing the waste of expensive raw materials. Bioactive ingredients are highly susceptible to environmental factors like light, heat, oxygen, shear stress, and harsh chemicals. Exposure to these elements can lead to degradation, resulting in the loss of their functional properties. The IN-AIR MICROFLUIDICS™ process is gentle, as it involves a low shear rate, doesn't require elevated temperatures (~5°C≤), and doesn't involve harsh solvents or emulsifiers to ensure the high survival of bioactive compounds, including biologics, probiotics, and nutraceuticals.