You can order DMC Dissolvable Microcarriers via our product page or by requesting a quote.

Over 1 billion cells in just 14 days

Our Dissolvable Microcarrier enables you to culture more cells; faster, easier, and at lower cost.

By fully dissolving during harvest, it offers gentle, high-yield cell recovery without mechanical separation. Compatible with standard cell culture reagents, it simplifies integration in your workflow, reduces downstream complexity, and improves overall efficiency.

"The Dissolvable Microcarriers (DMC-RG) from IamFluidics and Rousselot have provided an excellent platform for expanding and differentiating MSCs in our research on cartilage and bone regeneration. Their cell-friendly dissolution ensures high viability and recovery. This innovation has helped streamline our workflows without compromising the quality of our cells, making it a valuable tool for our tissue engineering applications."

— Eric Farrell’s Group, Erasmus MC

"We are thrilled to collaborate with IamFluidics, whose exceptional expertise and speed of innovation set them apart. By combining our high-quality denatured collagen with their advanced technology, our new dissolvable microcarrier offers the consistency and quality essential for large-scale production."

— Tanja Vervust, Global Director Biomedical at Rousselot

White Paper

Scaling up 3D cell cultures with advanced microencapsulation technology

Download our whitepaper to discover how recent advancements in microencapsulation technologies can improve the efficiency and consistency of 3D cell cultures, by more closely mimicking the native cellular environment, enhancing cell viability, and improving scalability.

Brochure Dissolvable Microcarriers

Dissolvable Microcarriers: Improving efficiency in cell culture and upscaling

Discover dissolvable microcarriers that enable efficient cell expansion and rapid, high-yield harvesting in bioreactors.

Download the brochure to learn how dissolvable microcarriers simplify scalable adherent cell culture.

Culture more cells with DMC Dissolvable Microcarriers

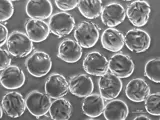

DMC is a biopolymer-based Dissolvable Microcarrier that consists of an ultra pure gelatin coated alginate microparticle. The premium gelatin from Rousselot Biomedial provides a physiological, soft cell-material interface that support a wide variety of adherent cell types, including mesenchymal stromal cells, iPSC/ESC-derived cells, VERO, CHO and HEK.

The gelatin coating promotes rapid cell attachment and growth.

With DMC Microcarriers, you can achieve faster cell growth and higher yields, reaching over 1 million cells per mL within 14 days. Their performance has been validated in a range of bioreactors, confirming robust and reproducible results.

Harvesting cells from non-dissolvable microcarriers can damage cells and results in about 50% precious cell loss. We gently and completely dissolve the microcarrier substrate to harvest the cells with an efficiency over 90%, nearly doubling your cell recovery without compromising your cell quality.

Easy integration into your workflow

DMC Dissolvable Microcarriers dissolve with standard cell culture reagents EDTA +TrypLE. You will obtain a single-cell suspension and fully dissolved biopolymers, without requiring mechanical separation steps to filter out the microcarriers and debris from your product. This will simplify the down steam processing and save cost.

In just 15 minutes after addition of EDTA and TrypLE, DMC microcarriers fully dissolve.

Validation and application

The DMC Dissolvable Microcarrier has been validated with a wide range of cell types, reactor designs and at different scales. We are working together with industry partners and users to build use cases and demonstrate its performance.

Trilineage differentiation of mesenchymal stromal cells (MSC) cultured in a 1.2L Osillaris bag reactor, generated by Fraunhofer Institute and Scinus Cell Expansion.

Cell encapsulation with IN-AIR-MICROFLUIDICS™

Scalable, gentle, and reproducible microencapsulation of living cells

Encapsulating cells into well-defined microcapsules enables controlled 3D cell culture in suspension while protecting cells from shear stress and uncontrolled aggregation. IN-AIR MICROFLUIDICS™ is a unique microencapsulation technology that makes this approach scalable, reproducible, and compatible with sensitive living cells.

Unlike conventional microfluidic or emulsion-based encapsulation methods, IN-AIR MICROFLUIDICS™ combines high-throughput jetting with precise, microfluidic-level control, enabling the continuous production of uniform, cell-laden microcapsules without the use of oils or toxic solvents.

Cells are encapsulated within a confined, protective microenvironment that supports nutrient and oxygen diffusion, controlled cell aggregation and tissue formation and waste removal. With IN-AIR-MICROFLUIDICS™, droplets are formed in air rather than in an oil phase, the process is inherently clean, biocompatible, and gentle, minimizing shear stress and preserving cell viability.

Compared to other techniques, our patented IN-AIR-MICROFLIUDICS™ technology offers unique benefits to enable cell encapsulation and cell therapies at relevant scale.

Reproducibility at scale

Uniform capsule size and composition ensure consistent 3D cell aggregates, reducing variability in viability, differentiation, and function.

Shear protection in bioreactors

Encapsulated cells are shielded from external shear forces, preventing uncontrolled merging, necrotic cores, and heterogeneous outcomes during suspension culture.

Xeno-free and biocompatible

Cell encapsulation can be performed using fully defined, xeno-free materials such as alginate, making the technology suitable for ATMP and GMP-oriented workflows.

On-demand cell retrieval

Capsules can be designed as sacrificial structures, allowing gentle release of cell aggregates using cytocompatible reagents such as PBS or enzymatic dissolution.

Frequently asked questions

For more information about DMC Dissolvable Microcarriers, check out our brochure and FAQ below, or get in contact with one of our experts.

Where can I order DMC Dissolvable microcarriers

My microcarriers do not dissolve, what should I do?

DMC Dissolvable Microcarriers consist of a alginate bead coated with crosslinked ultra pure gelatin. Both EDTA and Tryple are required to dissolve the microcarriers. If either one of these components is missing, the microcarriers might not fully dissolve.

Can DMC Dissolvable Microcarriers be autoclaved?

Yes, it is recommended to autoclave hydrated microcarriers before use. For a detailed description on how to use DMC Dissolvable Microcarriers please check out our Instruction for Use.

What is the surface area of DMC Dissolvable Microcarriers?

DMC Dissolvable Microcarriers have a surface area of 5000 cm² per gram.

What compounds remain after microcarrier dissolution?

Within 15 minutes after adding EDTA and TrypLE to dissolve your microcarriers you will obtain a single-cell suspension. Using SEC (size exclusion chromatography) we analyzed the harvest solution and observed polymer chains of alginate, short chains of gelatin, EDTA and TrypLE.

Are animal components in DMC Dissolvable Microcarriers posing a regulatory concern?

DMC Dissolvable Microcarriers show rapid cell attachment and growth. This is due to the physiological interaction of the gelatin coating with cells. We work together with Rousselot Biomedical and only use ultra pure, endotoxin controlled gelatin with excellent traceability to the farm (ISO 22442-2) and extensive documentation to ensure compliance with applicable legislation, including ISO 22442 standards and the latest EU Medical Device Regulation (EU) 2017/745 (MDR). Furthermore, it is validated for viral inactivation (ISO 22442-3).

Poster

Advancing high-quality bioreactor-scale cell culture using IN-AIR-MICROFLUIDICS™

Advancing high-quality bioreactor-scale cell culture with Dissolvable microcarriers and protective cell encapsulation using IN-AIR MICROFLUIDICS™. Download the ISCT 2024 poster

Poster

Dissolvable Microcarriers: Improving efficiency in cell culture and upscaling

Discover how dissolvable microcarriers and capsules enable high-viability, reproducible, and scalable cell culture using IN-AIR MICROFLUIDICS™. Download the poster to see the data presented at ISCT 2025.