Time for new possibilities

Many different industries use microencapsulation to preserve the performance of active ingredients and live cells, keeping them functioning and stable until the desired moment of release.

While current encapsulation methods fail to deliver microparticles with controlled precision and monodispersity at significant speed and volumes, our technology offers an unprecedented combination of performance, sustainability, and high efficiency to enable the use of microfluidics at an industrial-scale.

The need for performance, speed,

and gentle microencapsulation

It all started with two visionary scientists working with stem cell encapsulation for their academic research at the University of Twente, in The Netherlands.

Frustrated with the slow throughput, limited efficiency, and the interference of chemicals when using chip-based microfluidics, they invented a new technology called IN-AIR MICROFLUIDICS that was internationally awarded and published in high-impact scientific journals.

Our patented technology uses ink-jetting principles to encapsulate liquids in the air with high precision, control, and speed to produce state-of-the-art microparticles for batches of grams to multi-ton volumes using energy-efficient processes and sustainable materials.

Dr. Claas Willem Visser and Dr. Tom Kamperman,

IamFluidics' co-founders.

We develop sustainable microencapsulation solutions to address performance and scalability challenges with formulations, active ingredients, live cells, and biologicals.

IN-AIR MICROFLUIDICS™

patented technology

Revolutionary process

We use micrometer-sized liquid jets in the air to produce monodisperse microparticles ranging from 30μm to 3mm in diameter, with shape and size precision for topical, oral, injectable, and bioengineering applications.

Our technology does not use microfluidic chips, and the process is so gentle that even sensitive compounds, such as antioxidants, stem cells, probiotics, and biologicals, can survive and have their potency preserved, overperforming traditional microfluidics technologies.

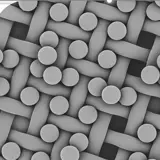

Picture of IamFluidics' microparticle production using the patented IN-AIR MICROFLUIDICS™ jetting system

Advanced formulations

Our unique process technology creates new possibilities to improve product performance, develop natural formulations without microplastics, and remove toxic chemicals from production.

Originally invented for biological applications, our technology has the potential to revolutionize healthcare products where microparticles can be used to enable controlled drug delivery, microbiome therapies, living cells, tissue regeneration, and cellular agriculture applications.

Microparticles revolution

Traditional methods to obtain microfluidics are limited by low throughput and lack of speed, making the use of precise microencapsulation only available to research and laboratory use for many years. IN-AIR MICROFLUIDICS' industrial scalability offers the opportunity to revolutionize formulations in nutritional products, cosmetics, and personal care to meet consumer demands for better sensory experiences, clean labels, vegan formulations, and natural ingredients.

Elevating performance

with monodisperse microparticles

Monodisperse microparticles present uniform size and shape, which improves encapsulation stability, efficiency, performance, sensory experience, ingestibility, and flowability, optimizing release kinetics for drug delivery.

One of the main challenges around monodispersity is related to the low precision of high-volume encapsulation methods and low volumes of monodisperse particle production with traditional chip microfluidics.

Our revolutionary in-air microfluidics technology is able to combine high throughput with high precision for sustainable production of monodisperse microparticles at an industrial scale, with size, shape, and material versatility.

Microscope picture of IamFluidics' monodisperse PLGA microparticles of 40µm

Material versatility and customization

Gentle, powerful and efficient microencapsulation

compatible with live cells, biomolecules, and sensitive APIs

low shear stress

no toxic solvents

no pre-treatment

high precision

high throughput

high efficiency

The need for performance, speed,

and gentle microencapsulation

It all started with two visionary scientists working with stem cell encapsulation for their academic research at the University of Twente, in The Netherlands.

Frustrated with the slow throughput, limited efficiency, and the interference of chemicals when using chip-based microfluidics, they invented a new technology called IN-AIR MICROFLUIDICS that was internationally awarded and published in high-impact scientific journals.

Our patented technology uses ink-jetting principles to encapsulate liquids in the air with high precision, control, and speed to produce state-of-the-art microparticles for batches of grams to multi-ton volumes using energy-efficient processes and sustainable materials.

Dr. Claas Willem Visser and Dr. Tom Kamperman,

IamFluidics' co-founders.

Test titel

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed fringilla felis justo, maximus sollicitudin libero blandit at. Etiam eleifend nisl et augue tincidunt, nec tincidunt metus molestie. Nullam iaculis eros vitae dictum iaculis. In imperdiet, tellus condimentum efficitur placerat, nisl dolor blandit dolor, in mattis mi orci id odio. Nam semper in libero non pharetra. Nullam molestie, velit at fringilla suscipit, dolor quam eleifend lacus, dictum suscipit neque orci nec mi.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed fringilla felis justo, maximus sollicitudin libero blandit at. Etiam eleifend nisl et augue tincidunt, nec tincidunt metus molestie. Nullam iaculis eros vitae dictum iaculis. In imperdiet, tellus condimentum efficitur placerat, nisl dolor blandit dolor, in mattis mi orci id odio. Nam semper in libero non pharetra. Nullam molestie, velit at fringilla suscipit, dolor quam eleifend lacus, dictum suscipit neque orci nec mi. Proin quis nulla interdum urna convallis fermentum a pulvinar lectus. Nulla sed iaculis justo. Vivamus venenatis diam sed pulvinar sollicitudin. Fusce porta mauris quis nibh bibendum, at porttitor lectus condimentum. Fusce nec varius nunc.

In ultricies nulla non ligula posuere, ut ultrices urna accumsan. Cras dapibus mollis venenatis. Duis condimentum blandit mollis. Duis sit amet gravida nisi. Ut odio lectus, faucibus eu gravida nec, tempus quis tellus. Praesent sit amet velit libero. Nam dictum molestie lorem, sed lobortis felis tristique id. Proin tempor dapibus augue ac pulvinar. Pellentesque eget ultricies ipsum. Duis pretium at sem sed consectetur. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam quis vulputate mauris, eu sollicitudin mi. Nunc ante risus, iaculis id finibus ac, sagittis vitae dolor.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed fringilla felis justo, maximus sollicitudin libero blandit at. Etiam eleifend nisl et augue tincidunt, nec tincidunt metus molestie. Nullam iaculis eros vitae dictum iaculis. In imperdiet, tellus condimentum efficitur placerat, nisl dolor blandit dolor, in mattis mi orci id odio. Nam semper in libero non pharetra. Nullam molestie, velit at fringilla suscipit, dolor quam eleifend lacus, dictum suscipit neque orci nec mi. Proin quis nulla interdum urna convallis fermentum a pulvinar lectus. Nulla sed iaculis justo. Vivamus venenatis diam sed pulvinar sollicitudin. Fusce porta mauris quis nibh bibendum, at porttitor lectus condimentum. Fusce nec varius nunc.